What’s the difference between CPM-154 vs 154CM? We almost titled this “A Tale of Two Steels” but steel is serious business, man. We’ll leave the quips for other articles. To be honest there’s not a lot of difference between the two steels. They’re a solid stainless-steel choice with a lot in common. They’re made by the same company, and have the same chemical composition. 154CM is almost as old as dirt. CPM-154 is not old as dirt. 154CM is a conventionally cast stainless-steel, while CPM-154 is powdered steel. The CPM process gives it a significantly higher toughness and better machinability than the 154CM. While CPM-154 may perform slightly better with day-to-day stuff than 154CM, most likely unless you’re a knife maker or sharpening fanatic, you’re probably not going to notice much difference between the two. [*]

What’s the difference between CPM-154 vs 154CM? We almost titled this “A Tale of Two Steels” but steel is serious business, man. We’ll leave the quips for other articles. To be honest there’s not a lot of difference between the two steels. They’re a solid stainless-steel choice with a lot in common. They’re made by the same company, and have the same chemical composition. 154CM is almost as old as dirt. CPM-154 is not old as dirt. 154CM is a conventionally cast stainless-steel, while CPM-154 is powdered steel. The CPM process gives it a significantly higher toughness and better machinability than the 154CM. While CPM-154 may perform slightly better with day-to-day stuff than 154CM, most likely unless you’re a knife maker or sharpening fanatic, you’re probably not going to notice much difference between the two. [*]

Cut to the chase. Are they expensive steels or budget steels?

That’s a whole soapbox for us here. There’s more that goes into the price of a knife than the cost of the steel. That said, neither steel is typically considered a budget steel. 154CM started out its knife-life in custom knives. CPM-154 is generally a more expensive option than 154CM. You can find knives with either of these steels across a number of price points.

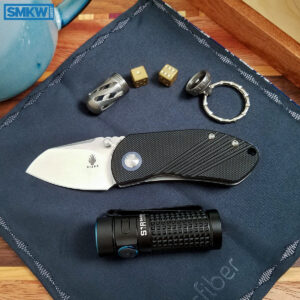

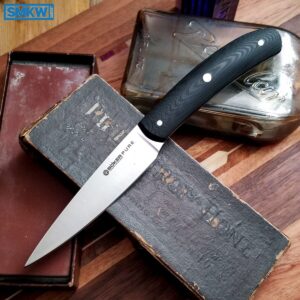

Knives with these steels run between the $60-ish and $200-ish range, depending on the knife and the maker and all sorts of other factors. For instance the Boker Pure CPM from the header and pictured below runs about $60. The new Kansept Copperhead with brown burlap micarta runs $99, and the Hogue X-1 MicroFlip with CPM 154 (pictured to the right) runs around $136, while the ProTech with 154CM runs close to $200. Why the variation? Well, there’s more to a knife than the steel used.

What is CPM-154 and 154CM?

CPM-154 and 154CM are both quality stainless-steels. They’re both high carbon, high chromium steels with very good corrosion and pitting resistance. We hear they’re both pretty easy to sharpen and do a fair job of holding an edge. One of the biggest differences between using these two blade steels is that CPM-154 (like in the Hogue MicroFlip pictured right) is almost double the toughness of 154CM.

History

According to KnifeSteelNerds, Crucible developed 154CM back in 1959 as a high-speed stainless bearing steel. For a time, it was apparently actually called an “improved 440C”. Bob Loveless popularized it amongst custom knifemakers when he began using it in his knives in 1972. Crucible made stair-step improvements in their steels over the decades. 440C is the first step. 154CM is an improved form of 440C. CPM-154 is an improved form of 154CM.

Data Sheets

Data Sheets

The Crucible datasheets tells us that CPM-154 and 154CM both contain 1.05% carbon (hardness), 14% chromium (stain resistance), and 4% molybdenum (carbide former that increases strength at high temperatures aka “hot hardness”, and increased corrosion resistance.) Other than the descriptors, the science-y parts of the data sheets for both CPM-154 and 154CM are the same.

However, in the descriptor parts of the data sheets, Crucible states, “CPM 154 is CPM-manufactured version of Crucible’s standard 154 CM. The CPM manufacturing process produces a uniform distribution of the carbides in this grade, giving this CPM 154 easier grinding and polishing, plus better toughness, than conventional 154 CM, while retaining similar heat treat response and wear properties.”

How can this be? Crucible answers, “The CPM process produces very homogenous, high quality steel characterized by superior dimensional stability, grindability, and toughness compared to steels produced by conventional processes.”

Let’s explain all that by oversimplifying a lot.

What’s the difference between powder metallurgy and conventional steel?

What’s the difference between powder metallurgy and conventional steel?

With conventionally cast steel, the steel makers mix iron and other metals into a vat. They melt them. They mix them together. Then they pour it into a mold to let it cool. This is generally a steel ingot. After that, it is re-heated, treated, and eventually turned into a knife blade by knife makers.

Powdered Steel is similar in concept to conventional steel. They take iron and other metals and pour them into a vat, and they melt them. Rather than directly pour the melted metal into large blocks, they funnel it through a liquid or a gas which instantly turns it into a powder which rapidly cools. Each of those tiny powdered particles is a wee small steel ingot. From there, there are number ways in which those tiny ingots are turned into blade steels, but generally, each of those teeny ingots go into another container, where they add heat and a lot of pressure which turns each teeny steel ingot into a big steel ingot. After that, it’s eventually re-heated, treated, and turned into a knife blade by knife makers.

The powder metallurgy processes result in a finer, more even grain structure. This means all the similarly sized particles kind of work together to improve your knife. Additionally, because of the way it is made and cooled, some metals don’t break down into or stay in small enough pieces to mix well with the conventional process. The steel ends up with inclusions or non-metal chemicals which are generally not beneficial to the steel. The powder metallurgy process fixes that problem.

Okay, so what does all that mean?

Okay, so what does all that mean?

With almost double the toughness, and significantly improved machinability, CPM-154 is the better knife steel. But unless you’re making knives (or you’re a fairly serious sharpening enthusiast) the machinability of the steel is as largely irrelevant to you as that scary Prop 65 warning. The end user experience is about the same. Thus, as we said in the beginning, the difference between the two steels doesn’t mean much to the regular knife user.

Both 154CM and CPM-154 will both work just fine to open your Doritos bags, your morning doughnut packages, and your daily knife delivery boxes. They’re highly stain and corrosion resistant steels that make for an excellent all-around, daily use. Think of 154CM as an improved 440C, and CPM-154 as a twice improved 440C.

Notes:

[*] Caveat: As we’ve said in other articles, “We majored in reading in college. We were thrilled to scrape by with a C in chemistry.” We aren’t metallurgists. We’re knife enthusiasts doing our best to navigate the complicated world of knife steel. If you’re super interested in the ins and outs of knife steel, you should absolutely follow Larrin Thomas at knifesteelnerds.com, and you should buy his book. He is a metallurgist. He knows of what he speaks. [**]Note: Any steel mistakes are ours alone and not a reflection on KnifeSteelNerds or Cruicible Industries.Sources:

www.crucible.com/PDFs%5CDataSheets2010%5CDatasheet%20CPM%20154%20CMv12010.pdf

www.crucible.com/PDFs/DataSheets2010/ds154cmv12010.pdf

knifesteelnerds.com/2018/05/21/154cm-development-properties-legacy/